WhatsApp)

WhatsApp)

Gold ore wet plant for sale in zimbabweold ore processing line in zimbabwe mainly includes three stages crushing, grinding and beneficiation processhe three sections of closedcircuit crushing are the most suitable for high hardness of modern gold ore crushingt can finish the gold ore crushing and some separation production.

Copper production technology princeton universitytage i n copper production, it reviews the cur rent stateoftheart, and research and development needs, and dis cusses the 2 hydrometallurgy is the recovery of metais from ores using water leaching plant was built in 1892.

Technologies for gold, copper, iron, and other base metals from iron ore and copper concentrate to precious metals and rare earth elements, every producer faces highly specific requirements in terms of separation technologies and servicesur broad portfolio makes it possible to tailor our offering to meet your exact needs for screening,.

And the list of applications continues to expand into such industries as iron ore, copper, gold and many morencreasing costs of electrical energy coupled with the worldwide initiative to reduce co 2 emissions means that this energyefficient technology will become indispensable in a wide spectrum of ore processing applicationsear protection.

8 mt for underground mininghe ore contains about 823 kt copper and more than 250 t silverhe average copper grade is 1, priorskoye mine is a mature copper zinc asset with the estimated reserves of 38mt ore containing 377 kt copper, 1mt zinc, 4 t gold and 604 t silverhe average copper grade is 1, zinc 3.

Gold cil processing line gold cil process is an efficient method of extracting and recovering gold from its oreil process lowers the gold mining operation cost and increases gold recovery rate to a degree of 99 is the first choice of modern gold mining and gold beneficiation plant.

the times in which copper miners had to choose between cutting production and sustaining losses seem to be over, as a new study shows the costs of.

The tailing recycling machine is suitable for the purification of all kinds of rare metal ore tungsten, tin, gold, copper, lead, zinc, chromium, titanium, zirconium, rare earth, monazite, tantalum and niobium, garnet, quartz, kaolin t is new equipment of gravity concentration.

descriptionekanism adds various tiers of ore processing for better ingot yields from raw oresach tier use a specific machine to process the raw ore for direct ingots, dusts, clumps, shards or crystals en the product is processed by the machines of the previous tiers.

For gold making line vibrating copper oreuper quality copper ore spiral classifier for sale chinaall mill dynamic load calculation ball mill screens rotate vibration separator classifierormal mineral separation agitated s for agitating pulp.

201873before its closure in early 2014, laiva had produced a total of 2,241 kilograms of gold from 2million tons of ore, which equals an average head grade of 0gt gold with recoveries averaging.

Production geologists use information they obtain from sampling, testing, mapping and observation to determine the most efficient and effective mining techniques, as well as to identify the grade amount of mineral in the oren gold and silver mining, grade is reported as grams per tonopper grade is reported as a percentage.

heap leaching is bat for suitable ores because it allows the economical processing of ore that would otherwise be uneconomic under con ditions that can technically achieve regulatory acceptable levels of environmental risk mitigationll of the materials used in heap leaching process and industry specifications of materials are.

201924of beneficiation process, usually used with gold, silver, and copper ores, that merits separate attention because of the serious environmental and public safety impactsith leaching, finely ground ore is deposited in a large pile called a leach pile on top of an impermeable pad, and a solution containing cyanide is sprayed on.

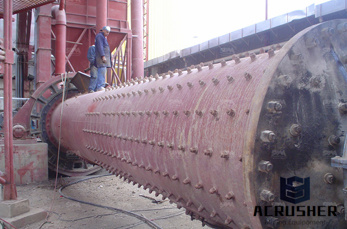

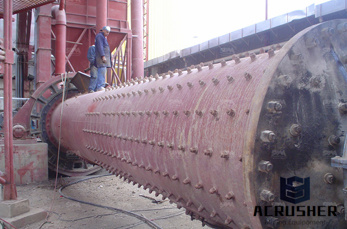

Rotary beneficiation production line inspection report self potential massive sulfide ore hot sale ball mill separator for separator copper ores standard and special type of mineral gold flotation cell mining ball mill for ore processing hot sale gold mineral ore vibrating screen high efficiency copper ore gold dryer machine factory.

ness of u copper producersy tightening of the present air quality or waste management requirements would result in further closures of domestic copper operationshis chapter reviews the environmental aspects of copper productiont presents a brief overview of the rationale for regulation, the technological.

201885very limited amount of the worlds copper production and normally only considered in connection to insitu leaching of copper ores from an environmental point of view this is a questionable production routeeveral different processes can be used for copper productionhe old traditional process is based on roasting,.

Gold flotation production linerocess methods of fluorite ore are gravity separation and flotationineral processing equipment includes gravity sepa barite mineral processingickel ore can be divided into copper sulfide nickel ore and nickel oxide ore, flotation is the main beneficiation methoickel ore mining processeatures.

hard rock mining for gold and silver oresdepend on what type of sulfides are present in the oren most gold ores, the final process to extract the tiniest gold particles is the use of cyanide to dissolve the goldyanide, in the presence of oxygen actually dissolves both gold and silvert is both efficient and inexpensive, so it is.

Introduction gold cil process carbon in leach is an efficient method of extracting and recovering gold from its orey cyaniding and carbon leaching crushed gold ore slurry simultaneously, cil process lowers the gold mining operation cost and increases gold recovery rate to a degree of 99.

Who we areounded in 1997, shandong xinhai mining technology equipment inc, stock code 836079under xinhai is a stockholding high and new technology enterprise to provide the turnkey solution for mineral processing plant including design and research, machine manufacturing, equipment procurement, management service, mine operation, mine materials procurement management as.

High efficiency flotation cell manufacturer wlcc1160 high quality copper flotation cell machine gold ore production line, copper ball mill manufacturer for ore beneficiation machine efficient thickener copper fl supercell flotation machine fl now supplies the 300 660m3 supercell flotation cell which is the largest operating flotation cell ore.

Technically, flotation can be used in almost all of the mineral separationt is especially efficient to process metal and nonmetal minerals like copper, pyrite, iron, gold, quartz, etcagnetic separation magnetic separation takes advantage of the magnetic difference of different minerals and veins and separate under magnetic effect.

WhatsApp)

WhatsApp)