WhatsApp)

WhatsApp)

Cement Manufacturing Process. The raw materials needed to produce cement (calcium carbonate, silica, alumina, and iron ore) are generally extracted from limestone rock, chalk, shale, or clay. These raw materials are won from the quarry by either extraction or blasting.

Environmental, Health, and Safety Guidelines CEMENT AND LIME MANUFACTURING APRIL 30, 2007 1 WORLD BANK GROUP Environmental, Health, and Safety Guidelines .

Cement Cement is a ˜ ne powder that is the principal strengthgiving and propertycontroling component of concrete. It is a high quality, costeffective building ...

The major raw materials for cement ... The entire manufacturing process is computer controlled ... from nearby states as and when required. The raw mix normally ...

Raw material preparation. From the quarry to raw meal feeding ... The manufacturing of cement begins with ... raw material to the size required by the

Cement, or Portland cement, is defined as "a hydraulic cement, obtained by burning a mixture of lime and clay to form a clinker, then pulverizing the clinker into powder.

Material cost is the major cost component of a garment manufacturing costs. A correct cost calculation method will give you better projection of garment cost for a style.

Cement manufacturing raw materials. If you happen to be a geologist, the raw materials quarry is probably the most interesting part of a cement works, maybe unless ...

The first step in making concrete is to prepare the cement. One type of cement, Pordand cement, is considered superior to natural cement because ...

japanese japanese clean technologies technologies for south african cement industry cement industry 6, september 2012

CEMENT RAW MATERIALS ... The raw materials which supply cement works, and which may be required in ... released during energy generation to power cement manufacturing

Building materials account for about half of all material use worldwide and about half the solid waste generated.

Cement manufacturing: components of a cement plant. This page and the linked pages below summarize the cement manufacturing process from the perspective of the ...

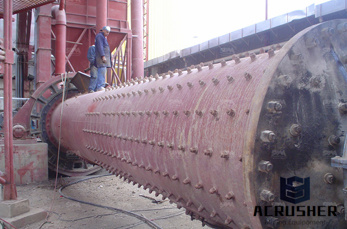

Portland Cement Manufacturing ... raw material processing operations differ somewhat for wet and ... 40 percent of the thermal energy is required in the rotary ...

Executive Summary ii Cement, Lime and Magnesium Oxide Manufacturing Industries and quantity of air pollution depend on different parameters, inputs (the raw ...

A cement is a binder, a substance used in construction that sets, hardens and adheres to other materials, binding them together. Cement is seldom used solely, but is ...

Special Economic Zone at Villayat, District Bharuch, Gujarat Jubliant Infrastructure Limited

Cement manufacturing raw materials. If you happen to be a geologist, the raw materials quarry is probably the most interesting part of a cement works, maybe unless you view the clinkering process as igneous rocks in the making. The most common raw rock types used in cement production are:

Back to top. INCOMING INSPECTION All raw materials, after being received in, are inspected to verify that their physical and electrical attributes are acceptable.

what are the raw materials required for manufacture of cement ... The raw materials needed to produce cement ... feed requirements The manufacturing of cement is ...

calculators, engineering, mechanical, electrical, electronics, design, construction, manufacturing, consultant, layout, software, chemical, plastic, polymers

We had a lot of raw material to work with and we had a lot of time in which to work with it and make something meaningful.

Sep 17, 2013· This video provides an overview of how to perform Critical Path Method (CPM) to find the Critical Path and Float using a ...

Structural steel is a category of steel used as a construction material for making structural steel shapes. A structural steel shape is a profile, formed with a ...

WhatsApp)

WhatsApp)