WhatsApp)

WhatsApp)

Vipeak Heavy Industry Machinery Group Company Provides You:Jaw Crusher,Sand Maker,Crusher,Hammer Crusher,Mobile Crusher,Grinder,Crushing Machine,Mill,Ball Mill .

Manufacturing and exporting of sand mills, open type sand mills, steel ball mills, sigma kneader, batch type blenders, open type sand mills, closed type sand mills ...

Cement history, in brief, from the Greeks and Romans to the development of Portland cement

Chemical Considerations. The raw material preparation stage of cement manufacture results in the production of a rawmix that is in a suitable state for feeding to the ...

EQUIPMENT RENTAL BUSINESS LIQUIDATION. Saturday July 15th – 10:00am. 6205 N. 89th Circle – Omaha, NE 68134. Trailers, Honda Gold Wing, Construction Equipment ...

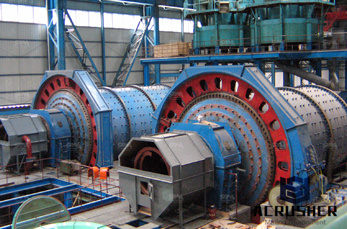

Cement Milling. Cement milling is usually carried out using ball mills with two or more separate chambers containing different sizes of grinding media (steel balls).

The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory ...

A pulverizer or grinder is a mechanical device for the grinding of many different types of materials. For example, a pulverizer mill is used to pulverize coal for ...

In this instructable we will see how to make a chainsaw mill, how to use it, and discuss some tips and tricks to the hidden and mystical art of planking up fallen trees.

coal hammer mill design[crusher and mill] Hammer Mill Design Mini Project – Free download as PDF File (.pdf), text . The basic design of the industrial hammer ...

Sep 17, 2013· This video provides an overview of how to perform Critical Path Method (CPM) to find the Critical Path and Float using a ...

The first step in making concrete is to prepare the cement. One type of cement, Pordand cement, is considered superior to natural cement because ...

Mill Classification System. Retrofits all types of vertical airswept mills (roller mills, bowl mills, hammer mills, cagemills impactors).

Ball Mill In A Cement Plant : The general mining methods are surface mining, while some silicates, such as sand, are commonly mined using dredges, from lakes ...

Ball Mills Ball Mills, and other forms of tumbling mills such as tube mills, rod mills and batch mills form a significant type of equipment used for the size ...

CEMENT INDUSTRY Output of a Seminar on Energy Conservation in Cement Industry Sponsored by United Nations Industrial Development Organization (UNIDO)

Technology: There are two basic types of cement production processes and a number of different kiln types. Cement production is either "wet" or "dry", depending on ...

Cement Manufacturing Process Phases. Production of cement completes after passing of raw materials from the following six phases. These are; Raw material extraction ...

The ATOX Raw Mill is a highly efficient mill that grinds all types of raw materials – saving both space and energy while delivering outstanding performance

The Emax is an entirely new type of ball mill for high energy milling. The Emax combines high friction and impact to create extremely fine particles.

Bolted shell liners, tube mill internals, boltless shell liners for cement mills from AIA Engineering Ltd.

Talk with the Experts at Paul O. Abbe about your process requirements and Ball Mill Loading, Wet Milling, Size Reduction and Mill Speed Critical Speed needs.

Crusher of Shibang ★ Shibang is a professional manufacturer of Granite Crusher ★ Feldspar crusher, Limestone Crushers produce Stone crusher, Grinder mill, Mobile ...

A stepbystep chronicle of how to do a CNC conversion on a milling machine.

WhatsApp)

WhatsApp)